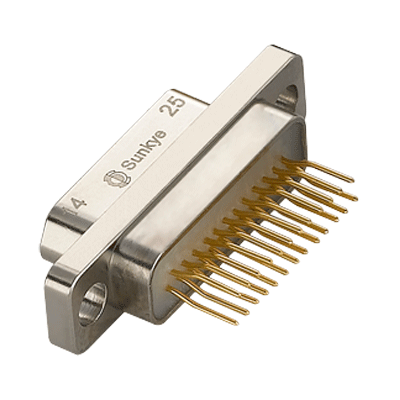

MIL-DTL-83513 Micro D Connectors

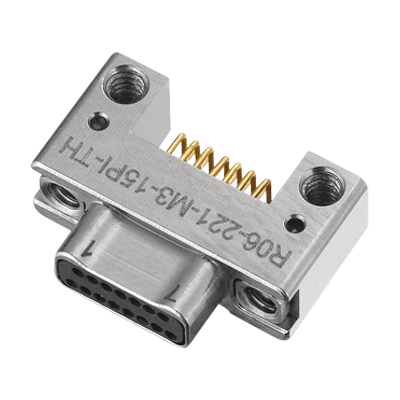

MIL-DTL-32139 Nano D Connectors

Discover more applications using Sunkye Connectors' solutions

Sunkye aims to develop tiny circular with high-pressure connectors

Benefits of Nano D Connectors:

Nano D connectors are known for their small size, which makes them ideal for use in applications where space is limited. Despite their small size, they offer high performance and reliability, making them suitable for use in harsh environments. These connectors are designed to withstand extreme temperatures, pressure, and vibration, which are common in the oil and gas industry. They also have a long lifespan and require minimal maintenance, reducing downtime and increasing productivity.

Applications of Nano D Connectors in the Oil and Gas Industry:

Downhole Drilling Tools: Sunkye Nano D connectors can be used in downhole drilling tools to provide a reliable connection between the tool and the control system. These connectors can withstand high temperatures and pressure, ensuring that the tool operates safely and efficiently.

Subsea Equipment: Subsea equipment used in offshore oil and gas exploration requires connectors that can withstand the harsh environment of the ocean floor. Sunkye Nano D connectors are ideal for this application due to their ability to withstand high pressure, corrosion, and extreme temperatures.

Pipeline Monitoring Systems: Pipeline monitoring systems require connectors that can transmit data reliably over long distances. Sunkye Nano D connectors can be used to create a secure connection between sensors and data collection systems, ensuring that pipeline operators have access to accurate information in real time.

Nano D connectors have several advantages over traditional connectors, including their size, weight, performance, and reliability. Their small size and light weight make them ideal for use in tight spaces and weight-sensitive applications. They also offer superior performance compared to traditional connectors, including higher current-carrying capacity, better signal integrity, and improved resistance to shock and vibration. In addition, Nano D connectors are designed to be highly reliable, with a low failure rate even in harsh environments.

In terms of size, Nano D connectors have a pitch size of 0.635 mm, making them the smallest circular connectors available in the market. This small size makes them ideal for use in applications where space is limited, such as in subsea equipment or drilling tools. The reduced size also means that they are lighter than traditional connectors, making them ideal for use in weight-sensitive applications. Nano D connectors are miniature connectors with a size of 0.635 mm pitch, making them the smallest circular connectors available in the market. They are designed to operate in extreme environments, including high temperatures, high pressures, and corrosive atmospheres. Nano D connectors are manufactured using advanced materials such as titanium, stainless steel, and ceramics, which offer superior strength and durability.

In terms of performance, Nano D connectors offer several advantages over traditional connectors. They have a higher current-carrying capacity, which means that they can handle more power than traditional connectors. They also have better signal integrity, which means that they can transmit signals more accurately and with less interference. Finally, they are more resistant to shock and vibration, which makes them ideal for use in drilling and production applications.

In terms of reliability, Nano D connectors are designed to be highly reliable, with a low failure rate even in harsh environments. They are made from advanced materials such as titanium, stainless steel, and ceramics, which offer superior strength and durability. They are also designed to resist corrosion, which is essential in the oil and gas industry where corrosive fluids and gases are common.

Applications of Nano D Connectors in the Oil and Gas Industry

Nano D connectors have various applications in the oil and gas industry, including:

1. Subsea Applications:

Subsea applications require connectors that can withstand high pressures and corrosive environments. Nano D connectors are ideal for subsea applications as they are designed to operate at depths of up to 10,000 feet. And temperature up to 200 ℃.

2.Drilling Applications:

Drilling operations require connectors that can withstand high temperatures and shock vibrations. Nano D connectors offer superior performance in these harsh environments.

3. Production Applications:

Production applications require connectors that can withstand corrosive fluids and gases. Nano D connectors are designed to resist corrosion, making them ideal for production applications.

Nano D connectors are becoming increasingly popular in the oil and gas industry due to their durability and reliability. Their small size also makes them suitable for use in portable equipment, such as handheld drilling tools. Advancements in nanotechnology are expected to further improve their performance.

Sunkye Nano D connectors have several advantages over traditional connectors, including:

1. Size: Nano D connectors are smaller than traditional connectors, making them ideal for use in tight spaces.

2. Weight: Nano D connectors are lighter than traditional connectors, making them ideal for use in weight-sensitive applications.

3. Performance: Nano D connectors offer superior performance compared to traditional connectors, including higher current carrying capacity, better signal integrity, and improved resistance to shock and vibration.

4. Reliability: Nano D connectors are designed to be highly reliable, with a low failure rate even in harsh environments.

Nano D connectors are a reliable solution for various applications in the oil and gas industry. With their small size, high performance, and durability, they are perfect for use in harsh environments. As the industry's need for dependable connector's increases, Nano D connectors are expected to have a crucial role to play. Overall, these connectors offer promising opportunities in the oil and gas sector. Their advanced design and materials make them perfect for use in demanding applications where performance and reliability are essential. With the oil and gas industry constantly evolving and demanding more advanced technologies, Sunkye Nano D connectors are poised to have an increasingly crucial role in this sector. This industry requires the most reliable and robust equipment, and the use of advanced technologies has become necessary to improve performance, safety, and efficiency. One of the most promising technological advancements is Nano D connectors, which are designed to withstand harsh environments and offer superior performance compared to traditional connectors.

Sunkye Connection Technologies provides a wide product portfolio with a complete interconnect solutions offering. Sunkye connectors and cables assemblies are complementary with Sunkye backshells and conduits.

Aug 02, 2020

Electrical Performance of Connector

Aug 02, 2020

Electrical Performance of Connector

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Feb 08, 2021

Four Attention Points in Using Power Connectors

Feb 08, 2021

Four Attention Points in Using Power Connectors

May 27, 2021

The Importance of Connectors in Electrical Equipment

May 27, 2021

The Importance of Connectors in Electrical Equipment

Nov 08, 2019

Miniaturization Development Technology Of Connector

Nov 08, 2019

Miniaturization Development Technology Of Connector

Sep 04, 2019

Market Profile of Micro PCB Connectors

Sep 04, 2019

Market Profile of Micro PCB Connectors

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Jan 31, 2020

The Development Of D-sub Connectors

Jan 31, 2020

The Development Of D-sub Connectors

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Jun 24, 2020

Application of Military Electrical Connectors (3)

Jun 24, 2020

Application of Military Electrical Connectors (3)

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Dec 26, 2019

How To Classify Industrial Connectors

Dec 26, 2019

How To Classify Industrial Connectors

Jun 12, 2020

7 Tips for Connector Design (1)

Jun 12, 2020

7 Tips for Connector Design (1)

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Nov 24, 2019

The Connector Applications Are Everywhere

Nov 24, 2019

The Connector Applications Are Everywhere

Dec 02, 2019

Basic Structural Member Of Connector

Dec 02, 2019

Basic Structural Member Of Connector

Dec 11, 2019

The Main Classification Of Crimp Connection

Dec 11, 2019

The Main Classification Of Crimp Connection

May 31, 2019

Sunkye Super Pin Connector

May 31, 2019

Sunkye Super Pin Connector

Jul 30, 2019

Market Status of Micro Connectors

Jul 30, 2019

Market Status of Micro Connectors

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Jul 06, 2020

Manual Assembly of Connectors (2)

Jul 06, 2020

Manual Assembly of Connectors (2)

Oct 19, 2021

Subsea Connector needs a new revolution

Oct 19, 2021

Subsea Connector needs a new revolution

Apr 01, 2020

Connectors for Special Applications

Apr 01, 2020

Connectors for Special Applications

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Jun 21, 2020

Application of Military Electrical Connectors (2)

Jun 21, 2020

Application of Military Electrical Connectors (2)

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

Mar 20, 2020

Connector Quality Test Type

Mar 20, 2020

Connector Quality Test Type

Jun 27, 2020

Crimping and Welding of Military Connectors

Jun 27, 2020

Crimping and Welding of Military Connectors

Oct 06, 2020

Description of Pogo Pin Connectors

Oct 06, 2020

Description of Pogo Pin Connectors

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Nov 15, 2019

How To Make High-Quality Connector

Nov 15, 2019

How To Make High-Quality Connector

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

May 31, 2019

Everything You Need to Know: Type C

May 31, 2019

Everything You Need to Know: Type C

Dec 08, 2019

Connection Methods Of The Connector

Dec 08, 2019

Connection Methods Of The Connector

Aug 09, 2021

What Are High Density Connectors?

Aug 09, 2021

What Are High Density Connectors?

Nov 10, 2019

The Future Trend Of Automobile Connector

Nov 10, 2019

The Future Trend Of Automobile Connector

Jul 03, 2020

Manual Assembly of Connectors (1)

Jul 03, 2020

Manual Assembly of Connectors (1)

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Jul 21, 2020

What is a Military Specification Circular Connector?

Jul 21, 2020

What is a Military Specification Circular Connector?

Jan 22, 2020

Differences Between Connector And Terminal

Jan 22, 2020

Differences Between Connector And Terminal

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Aug 07, 2019

A Revolution in Connector Technology

Aug 07, 2019

A Revolution in Connector Technology

Sep 19, 2020

The Necessity of Waterproof Connectors

Sep 19, 2020

The Necessity of Waterproof Connectors

Jan 11, 2021

How to Select Connectors for Hardware Design

Jan 11, 2021

How to Select Connectors for Hardware Design

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Dec 22, 2020

The Transient Interruption Detection of Connectors

Dec 22, 2020

The Transient Interruption Detection of Connectors

Feb 10, 2020

The Function And Prospect Of Medical Connector

Feb 10, 2020

The Function And Prospect Of Medical Connector

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Sep 02, 2019

Four Processes of Producing Connectors

Sep 02, 2019

Four Processes of Producing Connectors

Sep 26, 2019

Market Status of Micro Miniature Connectors

Sep 26, 2019

Market Status of Micro Miniature Connectors

May 31, 2019

SUNKYE will Release Type C Project on October

May 31, 2019

SUNKYE will Release Type C Project on October

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Apr 28, 2020

How to Detect Medical Connectors

Apr 28, 2020

How to Detect Medical Connectors

Oct 13, 2020

Various Coaxial Connectors

Oct 13, 2020

Various Coaxial Connectors

Jan 18, 2021

Knowledge of FPC Connectors

Jan 18, 2021

Knowledge of FPC Connectors

May 31, 2019

Features of Type C

May 31, 2019

Features of Type C

Oct 31, 2019

The Introduction Of SMT

Oct 31, 2019

The Introduction Of SMT

Jan 04, 2021

The Structure and Material of Connectors

Jan 04, 2021

The Structure and Material of Connectors

Nov 17, 2020

Selection Factors for SMA Connectors

Nov 17, 2020

Selection Factors for SMA Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Jul 15, 2020

Classification of Connectors

Jul 15, 2020

Classification of Connectors

Sep 24, 2019

Notes for Welding D Type Connector

Sep 24, 2019

Notes for Welding D Type Connector

Nov 29, 2019

Importance Of Connectors

Nov 29, 2019

Importance Of Connectors

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Oct 30, 2019

D Sub Connector Introduction

Oct 30, 2019

D Sub Connector Introduction

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Oct 06, 2019

How Military Spec Connectors Work

Oct 06, 2019

How Military Spec Connectors Work

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Sep 08, 2019

What are Avionics Connectors?

Sep 08, 2019

What are Avionics Connectors?

Apr 25, 2020

The Second Generation Circular Military Connector

Apr 25, 2020

The Second Generation Circular Military Connector

Jan 01, 2020

Development Trend Of Automobile Connector In China

Jan 01, 2020

Development Trend Of Automobile Connector In China

Jan 13, 2020

Overall Performance Parameters Of Connector

Jan 13, 2020

Overall Performance Parameters Of Connector

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Jun 25, 2019

Sunkye Super Pin Datasheet

Jun 25, 2019

Sunkye Super Pin Datasheet

Jul 17, 2020

Sunkye Market Matrix

Jul 17, 2020

Sunkye Market Matrix

May 31, 2019

Sunkye Type C 10Gbps Test on April

May 31, 2019

Sunkye Type C 10Gbps Test on April

Jun 18, 2020

Application of Military Electrical Connectors (1)

Jun 18, 2020

Application of Military Electrical Connectors (1)

Apr 04, 2020

The Material of the Connector

Apr 04, 2020

The Material of the Connector

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Jul 12, 2020

Introduction to the Connector

Jul 12, 2020

Introduction to the Connector

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Jul 18, 2020

The Basic Structure of the Connector

Jul 18, 2020

The Basic Structure of the Connector

Nov 17, 2023

Future Development Trends of Circular Connectors

Nov 17, 2023

Future Development Trends of Circular Connectors

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Aug 02, 2021

Introduction to Vehicle Connectors

Aug 02, 2021

Introduction to Vehicle Connectors

Nov 12, 2019

Production Technology of Connector

Nov 12, 2019

Production Technology of Connector

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Aug 03, 2019

Connector D Type

Aug 03, 2019

Connector D Type

Nov 11, 2019

Brief Introduction Of Automobile Connector

Nov 11, 2019

Brief Introduction Of Automobile Connector

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Sep 25, 2020

Related Knowledge of SMA RF Connector

Sep 25, 2020

Related Knowledge of SMA RF Connector

Nov 14, 2019

How To Choose The Right Connector

Nov 14, 2019

How To Choose The Right Connector

Aug 09, 2019

Development of Micro Connector

Aug 09, 2019

Development of Micro Connector

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

May 04, 2020

Automotive Connectors

May 04, 2020

Automotive Connectors

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Dec 29, 2019

Material Of Automotive Connectors

Dec 29, 2019

Material Of Automotive Connectors

Feb 13, 2020

Connection Between Brain And Machine

Feb 13, 2020

Connection Between Brain And Machine

Jan 04, 2023

Four Connection Methods of Circular Connectors

Jan 04, 2023

Four Connection Methods of Circular Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Sep 13, 2020

Fusion of Connectors and Sensors

Sep 13, 2020

Fusion of Connectors and Sensors

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Sep 18, 2019

Definition of Mil Standard Connector

Sep 18, 2019

Definition of Mil Standard Connector

Sep 20, 2019

Strictness of Military/Aerospace Specifications

Sep 20, 2019

Strictness of Military/Aerospace Specifications

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Apr 07, 2020

Market Status of Miniature Connectors

Apr 07, 2020

Market Status of Miniature Connectors

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Feb 25, 2020

How to Choose the Right Medical Connector

Feb 25, 2020

How to Choose the Right Medical Connector

Dec 23, 2019

Technical Principles Of Connectors

Dec 23, 2019

Technical Principles Of Connectors

Dec 08, 2020

Some Knowledge about RJ45 Connector

Dec 08, 2020

Some Knowledge about RJ45 Connector

Jan 16, 2020

Brief Introduction Of Strip Connector

Jan 16, 2020

Brief Introduction Of Strip Connector

Nov 09, 2019

Introduction To Connector Knowledge

Nov 09, 2019

Introduction To Connector Knowledge

Nov 01, 2019

Five Common Features of USB Connector

Nov 01, 2019

Five Common Features of USB Connector

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Nov 04, 2019

How Military Connectors Work

Nov 04, 2019

How Military Connectors Work

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Jun 15, 2020

7 Tips for Connector Design (2)

Jun 15, 2020

7 Tips for Connector Design (2)

Dec 14, 2019

Naming Of Connectors

Dec 14, 2019

Naming Of Connectors

Oct 01, 2020

Structure and Material of Waterproof Connector

Oct 01, 2020

Structure and Material of Waterproof Connector

Apr 22, 2020

Production Process of Connector Contacts

Apr 22, 2020

Production Process of Connector Contacts

Jan 28, 2020

The Connector Industry Is Booming

Jan 28, 2020

The Connector Industry Is Booming

Jan 07, 2020

The Performance Of Automobile Connector

Jan 07, 2020

The Performance Of Automobile Connector

Nov 06, 2019

Connector Classification

Nov 06, 2019

Connector Classification

Dec 17, 2019

Interconnection Level Of Connector

Dec 17, 2019

Interconnection Level Of Connector

Oct 13, 2020

Selection Factors of RF Connectors

Oct 13, 2020

Selection Factors of RF Connectors

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Oct 20, 2020

The Failure Mechanism of Connectors

Oct 20, 2020

The Failure Mechanism of Connectors

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

GET IN TOUCH

MIL-DTL-32139 Nano D Connectors

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  Türkçe

Türkçe  Svenska

Svenska  Nederland

Nederland