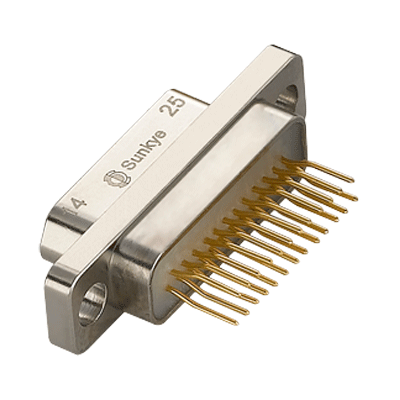

MIL-DTL-83513 Micro D Connectors

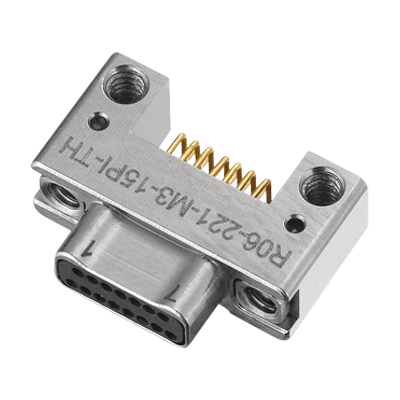

MIL-DTL-32139 Nano D Connectors

Discover more applications using Sunkye Connectors' solutions

Nowadays, the continuous advancement of waterproof connector technology has enabled the industry to develop many new connectors to meet the needs of different groups of people. For this product, its electrical performance is the focus of many people's concerns. Let's introduce some of its main electrical properties.

⑴ Contact resistance

This is a very common electrical performance in waterproof connectors. The contact resistance of a high-quality connector should be relatively stable. Generally, its resistance fluctuations can range from a few milliohms to tens of milliohms.

⑵ Insulation resistance of waterproof plug

The insulation resistance of a waterproof rectangular connector is also one of the main indicators of its electrical performance. The insulation resistance can measure the insulation performance between the connector's contact and the shell. According to industry regulations, its insulation range reaches hundreds of megohms to from several hundred to several thousand megaohms.

In addition, rectangular waterproof connectors have other electrical properties, such as reflection coefficient, characteristic impedance, current and so on.

In different circuits, the types of PCB rectangular connectors used are different. Therefore, when the manufacturer is plating rectangular PCB connectors, they will also treat them differently. Tinned, gold-plated, and copper-plated are several common electroplating methods.

At present, tin plating of rectangular connectors is more common, and the price of tin is relatively cheap, but because the texture of tin is not hard enough, it is easy to cause poor contact and low insertion and less removal times in the connector, and it can only play a role of relatively simple anti-corrosion effect.

Pure tin plating, the working temperature is relatively low, but the use of brass tin plating or bronze tin plating can significantly increase the working temperature, and the working temperature of steel tin plating can even reach 190°C.

If a large number of insertions and removals are required and the contact force is small, then the surface of the rectangular PCB connector needs to be gold-plated, and gold-plated can also improve the corrosion resistance of the product.

Many times people will use nickel as a gold-plated base layer. Some rectangular PCB connectors are plated with silver. Silver has very good conductivity. However, the characteristic of silver is that it is very easy to oxidize. Therefore, rectangular connectors are rarely plated with silver.

Sunkye is unique, able to provide turnkey customized solutions and military specification military connector manufacturers for a variety of high-performance applications. Our industry-leading material knowledge, engineering design experience, and testing capabilities are the keys to achieving reliable service in the most extreme environments. If you have any question, please feel free to consult us.

Sunkye Connection Technologies provides a wide product portfolio with a complete interconnect solutions offering. Sunkye connectors and cables assemblies are complementary with Sunkye backshells and conduits.

Dec 14, 2019

Naming Of Connectors

Dec 14, 2019

Naming Of Connectors

Apr 07, 2020

Market Status of Miniature Connectors

Apr 07, 2020

Market Status of Miniature Connectors

Jul 18, 2020

The Basic Structure of the Connector

Jul 18, 2020

The Basic Structure of the Connector

Jun 15, 2020

7 Tips for Connector Design (2)

Jun 15, 2020

7 Tips for Connector Design (2)

Oct 06, 2020

Description of Pogo Pin Connectors

Oct 06, 2020

Description of Pogo Pin Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Nov 10, 2020

Applications and Characteristics of BNC Connectors

May 04, 2020

Automotive Connectors

May 04, 2020

Automotive Connectors

Jul 21, 2020

What is a Military Specification Circular Connector?

Jul 21, 2020

What is a Military Specification Circular Connector?

Mar 20, 2020

Connector Quality Test Type

Mar 20, 2020

Connector Quality Test Type

Dec 08, 2020

Some Knowledge about RJ45 Connector

Dec 08, 2020

Some Knowledge about RJ45 Connector

Jan 18, 2021

Knowledge of FPC Connectors

Jan 18, 2021

Knowledge of FPC Connectors

Apr 04, 2020

The Material of the Connector

Apr 04, 2020

The Material of the Connector

Nov 17, 2023

Future Development Trends of Circular Connectors

Nov 17, 2023

Future Development Trends of Circular Connectors

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Nov 24, 2019

The Connector Applications Are Everywhere

Nov 24, 2019

The Connector Applications Are Everywhere

Nov 06, 2019

Connector Classification

Nov 06, 2019

Connector Classification

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Feb 10, 2020

The Function And Prospect Of Medical Connector

Feb 10, 2020

The Function And Prospect Of Medical Connector

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Apr 01, 2020

Connectors for Special Applications

Apr 01, 2020

Connectors for Special Applications

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jul 08, 2021

Structural Analysis of Aerospace Connector

Aug 02, 2021

Introduction to Vehicle Connectors

Aug 02, 2021

Introduction to Vehicle Connectors

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Sep 20, 2019

Strictness of Military/Aerospace Specifications

Sep 20, 2019

Strictness of Military/Aerospace Specifications

May 31, 2019

Sunkye Type C 10Gbps Test on April

May 31, 2019

Sunkye Type C 10Gbps Test on April

Oct 20, 2020

The Failure Mechanism of Connectors

Oct 20, 2020

The Failure Mechanism of Connectors

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Nov 17, 2020

Selection Factors for SMA Connectors

Nov 17, 2020

Selection Factors for SMA Connectors

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Oct 13, 2020

Selection Factors of RF Connectors

Oct 13, 2020

Selection Factors of RF Connectors

Sep 19, 2020

The Necessity of Waterproof Connectors

Sep 19, 2020

The Necessity of Waterproof Connectors

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Aug 02, 2020

Electrical Performance of Connector

Aug 02, 2020

Electrical Performance of Connector

Nov 10, 2019

The Future Trend Of Automobile Connector

Nov 10, 2019

The Future Trend Of Automobile Connector

Oct 19, 2021

Subsea Connector needs a new revolution

Oct 19, 2021

Subsea Connector needs a new revolution

Jul 17, 2020

Sunkye Market Matrix

Jul 17, 2020

Sunkye Market Matrix

Nov 29, 2019

Importance Of Connectors

Nov 29, 2019

Importance Of Connectors

Dec 02, 2019

Basic Structural Member Of Connector

Dec 02, 2019

Basic Structural Member Of Connector

Dec 26, 2019

How To Classify Industrial Connectors

Dec 26, 2019

How To Classify Industrial Connectors

Sep 13, 2020

Fusion of Connectors and Sensors

Sep 13, 2020

Fusion of Connectors and Sensors

Apr 22, 2020

Production Process of Connector Contacts

Apr 22, 2020

Production Process of Connector Contacts

May 31, 2019

Everything You Need to Know: Type C

May 31, 2019

Everything You Need to Know: Type C

Dec 22, 2020

The Transient Interruption Detection of Connectors

Dec 22, 2020

The Transient Interruption Detection of Connectors

May 31, 2019

Features of Type C

May 31, 2019

Features of Type C

Nov 08, 2019

Miniaturization Development Technology Of Connector

Nov 08, 2019

Miniaturization Development Technology Of Connector

Jan 07, 2020

The Performance Of Automobile Connector

Jan 07, 2020

The Performance Of Automobile Connector

Jan 01, 2020

Development Trend Of Automobile Connector In China

Jan 01, 2020

Development Trend Of Automobile Connector In China

Jan 13, 2020

Overall Performance Parameters Of Connector

Jan 13, 2020

Overall Performance Parameters Of Connector

Jan 22, 2020

Differences Between Connector And Terminal

Jan 22, 2020

Differences Between Connector And Terminal

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Oct 06, 2019

How Military Spec Connectors Work

Oct 06, 2019

How Military Spec Connectors Work

Aug 09, 2021

What Are High Density Connectors?

Aug 09, 2021

What Are High Density Connectors?

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Jun 24, 2020

Application of Military Electrical Connectors (3)

Jun 24, 2020

Application of Military Electrical Connectors (3)

Sep 02, 2019

Four Processes of Producing Connectors

Sep 02, 2019

Four Processes of Producing Connectors

May 27, 2021

The Importance of Connectors in Electrical Equipment

May 27, 2021

The Importance of Connectors in Electrical Equipment

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Feb 13, 2020

Connection Between Brain And Machine

Feb 13, 2020

Connection Between Brain And Machine

Jun 21, 2020

Application of Military Electrical Connectors (2)

Jun 21, 2020

Application of Military Electrical Connectors (2)

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

Nov 01, 2019

Five Common Features of USB Connector

Nov 01, 2019

Five Common Features of USB Connector

Oct 31, 2019

The Introduction Of SMT

Oct 31, 2019

The Introduction Of SMT

Jul 30, 2019

Market Status of Micro Connectors

Jul 30, 2019

Market Status of Micro Connectors

Aug 03, 2019

Connector D Type

Aug 03, 2019

Connector D Type

Dec 29, 2019

Material Of Automotive Connectors

Dec 29, 2019

Material Of Automotive Connectors

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Nov 09, 2019

Introduction To Connector Knowledge

Nov 09, 2019

Introduction To Connector Knowledge

Sep 04, 2019

Market Profile of Micro PCB Connectors

Sep 04, 2019

Market Profile of Micro PCB Connectors

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Jul 15, 2020

Classification of Connectors

Jul 15, 2020

Classification of Connectors

Apr 25, 2020

The Second Generation Circular Military Connector

Apr 25, 2020

The Second Generation Circular Military Connector

May 31, 2019

SUNKYE will Release Type C Project on October

May 31, 2019

SUNKYE will Release Type C Project on October

Sep 18, 2019

Definition of Mil Standard Connector

Sep 18, 2019

Definition of Mil Standard Connector

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Jun 18, 2020

Application of Military Electrical Connectors (1)

Jun 18, 2020

Application of Military Electrical Connectors (1)

Dec 17, 2019

Interconnection Level Of Connector

Dec 17, 2019

Interconnection Level Of Connector

Sep 24, 2019

Notes for Welding D Type Connector

Sep 24, 2019

Notes for Welding D Type Connector

Nov 15, 2019

How To Make High-Quality Connector

Nov 15, 2019

How To Make High-Quality Connector

Oct 30, 2019

D Sub Connector Introduction

Oct 30, 2019

D Sub Connector Introduction

Nov 14, 2019

How To Choose The Right Connector

Nov 14, 2019

How To Choose The Right Connector

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Aug 07, 2019

A Revolution in Connector Technology

Aug 07, 2019

A Revolution in Connector Technology

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Apr 28, 2020

How to Detect Medical Connectors

Apr 28, 2020

How to Detect Medical Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Aug 09, 2019

Development of Micro Connector

Aug 09, 2019

Development of Micro Connector

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Jul 06, 2020

Manual Assembly of Connectors (2)

Jul 06, 2020

Manual Assembly of Connectors (2)

Sep 25, 2020

Related Knowledge of SMA RF Connector

Sep 25, 2020

Related Knowledge of SMA RF Connector

Sep 08, 2019

What are Avionics Connectors?

Sep 08, 2019

What are Avionics Connectors?

Feb 08, 2021

Four Attention Points in Using Power Connectors

Feb 08, 2021

Four Attention Points in Using Power Connectors

Sep 26, 2019

Market Status of Micro Miniature Connectors

Sep 26, 2019

Market Status of Micro Miniature Connectors

Dec 08, 2019

Connection Methods Of The Connector

Dec 08, 2019

Connection Methods Of The Connector

Jan 11, 2021

How to Select Connectors for Hardware Design

Jan 11, 2021

How to Select Connectors for Hardware Design

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Jul 12, 2020

Introduction to the Connector

Jul 12, 2020

Introduction to the Connector

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

Feb 25, 2020

How to Choose the Right Medical Connector

Feb 25, 2020

How to Choose the Right Medical Connector

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Jan 28, 2020

The Connector Industry Is Booming

Jan 28, 2020

The Connector Industry Is Booming

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Oct 13, 2020

Various Coaxial Connectors

Oct 13, 2020

Various Coaxial Connectors

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Jun 27, 2020

Crimping and Welding of Military Connectors

Jun 27, 2020

Crimping and Welding of Military Connectors

Jan 16, 2020

Brief Introduction Of Strip Connector

Jan 16, 2020

Brief Introduction Of Strip Connector

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Oct 01, 2020

Structure and Material of Waterproof Connector

Oct 01, 2020

Structure and Material of Waterproof Connector

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Nov 12, 2019

Production Technology of Connector

Nov 12, 2019

Production Technology of Connector

May 31, 2019

Sunkye Super Pin Connector

May 31, 2019

Sunkye Super Pin Connector

Jun 12, 2020

7 Tips for Connector Design (1)

Jun 12, 2020

7 Tips for Connector Design (1)

Jul 03, 2020

Manual Assembly of Connectors (1)

Jul 03, 2020

Manual Assembly of Connectors (1)

Jan 31, 2020

The Development Of D-sub Connectors

Jan 31, 2020

The Development Of D-sub Connectors

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Dec 11, 2019

The Main Classification Of Crimp Connection

Dec 11, 2019

The Main Classification Of Crimp Connection

Nov 04, 2019

How Military Connectors Work

Nov 04, 2019

How Military Connectors Work

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Jan 04, 2021

The Structure and Material of Connectors

Jan 04, 2021

The Structure and Material of Connectors

Nov 11, 2019

Brief Introduction Of Automobile Connector

Nov 11, 2019

Brief Introduction Of Automobile Connector

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Dec 23, 2019

Technical Principles Of Connectors

Dec 23, 2019

Technical Principles Of Connectors

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Jun 25, 2019

Sunkye Super Pin Datasheet

Jun 25, 2019

Sunkye Super Pin Datasheet

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Jan 04, 2023

Four Connection Methods of Circular Connectors

Jan 04, 2023

Four Connection Methods of Circular Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

GET IN TOUCH

MIL-DTL-32139 Nano D Connectors

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  Türkçe

Türkçe  Svenska

Svenska  Nederland

Nederland