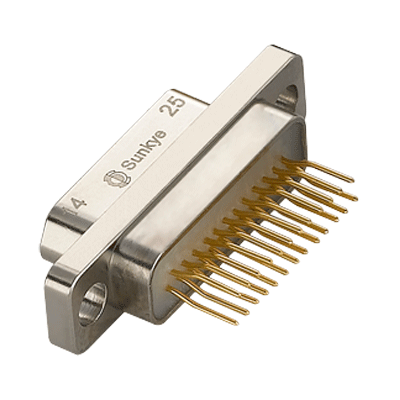

MIL-DTL-83513 Micro D Connectors

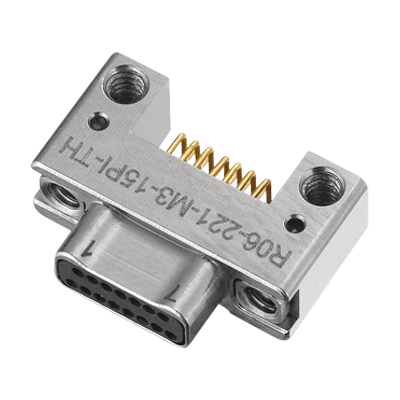

MIL-DTL-32139 Nano D Connectors

Discover more applications using Sunkye Connectors' solutions

The market for various high-end electronic products is growing rapidly, and the global production capacity of connectors is continuously shifting to Asia and China, so Asia has become the most promising place for connector development (pin header and female header), and China will become the fastest-growing and the largest connector market in the world. It is estimated that the growth rate of China's connector market will continue to exceed the global average level in the future. In the next five years, the annual growth rate of China's connector market will reach 15%. By 2010, China's connector market capacity will reach 25.7 billion yuan.

The main types of military power connectors are FPC connectors and SATA connectors. The supporting fields of the connectors include transportation, communication, network, IT, medical care, home appliances, etc. The rapid development of the product technical level in the supporting fields and the rapid growth of the market strongly drive the development of connector technology. So far, connectors have developed into serialization and specialization products with complete product categories, rich variety specifications, diverse structure types, professional direction subdivisions, obvious industry characteristics and standard system specifications.

Generally, the development of connector technology shows the following characteristics: high speed and digitization of signal transmission, the integration of all kinds of signal transmission, the miniaturization and micromation of product volume, low cost of products, the surface-mount terminating of contact parts, the combination of modules, the convenience of plug and plug, etc. The above technologies represent the development direction of connector technology, but it should be noted that the above technologies are not necessary for all connectors. Connectors in different supporting fields and different using environments have completely different demand points for the above technologies.

At present, the functions of electronic products are becoming more and more powerful and comprehensive, which puts forward higher and more diversified demands for connectors. For example, the transmission rate of electronic devices is getting higher and higher, and in order to meet the transmission and exchange of large traffic data, the requirements of high-speed transmission and digital transmission are put forward for connectors. However, more and more signals such as microwave signal, optical signal, high voltage signal and power signal are needed to be integrated into the same connector to save the space of the equipment and reduce the size of the equipment. Meanwhile, signals are required to be transmitted independently without interference, which determines that the development trend of connector signal transmission integration will be more and more obvious.

The market demand for the centralization and miniaturization of connectors has promoted the innovation in terminal technology. Semiconductor chip technology is becoming the technical driving force for the connector development at all levels of interconnection. For example, with the rapid development from the chip packaging of 0.5 mm spacing to the chip packaging of 0.25 mm spacing, the pin number of class I interconnect devices (inside IC devices) and class II interconnect devices (the interconnection of device and board) ranges from hundreds of lines to thousands of lines. Press-fit contact technology is widely used in cylindrical slotted sockets, elastic strand pins and hyperboloid spring socket connectors, which greatly improves the reliability of the connector and ensures the high fidelity of signal transmission.

Terminal technology enables connectors to constitute a new connector product, the push-in connector, which is primarily used for system-level interconnection. The biggest advantages are that it does not need cables, is easy to install and disassemble, and is convenient to replace on site. In addition, the insertion speed is fast, the separation is smooth and stable, and high frequency response can be obtained, which is suitable for spacecrafts. The military connector assembly technology is developing from plug-in installation technology to surface-mount technology, and the development trend is towards micro-assembly technology in the future. The adoption of MEMS (micro electro mechanical system) will be the power to improve the connector technology and cost performance.

Now pin headers and female headers are applied to more and more fields and industries. What are the main application fields of pin headers and female headers? Here are the details about the answer.

Although pin headers and female headers have the standard of hot plugs, the current pin headers are mostly designed for HDD, and the maximum plugging and pulling time is only about 200 times. If the plugging and pulling time is beyond the limit, the pin PCB connector will deteriorate and the hard disk may even be damaged. The plugging and pulling time of pin headers used for external applications is only about 2,500 times.

Driven by technological progress and cost reduction of pin headers and female headers, the technological strength and industrial position of pin headers will determine the development speed of related enterprises in China, because the emergence of new technology requires electronic enterprises to keep pace with the progress of technologies, and the position of the industry also determines the position of enterprises in the upstream and downstream price negotiations.

In large and medium-sized cities, flat-panel TV has entered the substantive popularization stage, but facing the complex prices, sizes and pin headers, the complicated technological functions and the mixture of high-end and low-end products, many consumers feel confused. Improving the production process of pin headers and female headers not only simplifies the assembly process of electronic products, but also simplifies the mass production process and the maintenance. In case of the failure of an electronic component, the failure component can be replaced quickly for upgrading when it is equipped with pin headers and female headers. With the progress of technology, the component can be updated when equipped with pin headers.

In recent years, the market demand for pin headers and female headers has maintained a high growth rate. The emergence of new materials and new technologies has also greatly promoted the improvement of industrial application level. At present, the development trend of the pin header and female header market is getting better and better, and pin headers and female headers can realize their own value in different fields.

In view of the improvement of miniaturization and intelligence level of pin header and female header technology, it is an inevitable trend to integrate multiple functions on the basis of information acquisition, and the data fusion technology of multiple pin headers and female headers also promotes the development of this technology. The integration of local data resources provided by multiple pin headers and female headers of various or different classes that are distributed in different locations and the adoption of computer technology analysis can eliminate the redundancy and contradiction between the information, provide complementary functions, reduce information uncertainty and obtain the consistent interpretation and description of the tested object, so as to improve the rapidity and correctness of the decision-making, planning and response of the system, and make the system obtain more adequate information. The information fusion occurs at different information levels, including data layer fusion, image feature layer fusion and decision-making level fusion.

Compared with single pin header and female header, the information of multiple pin headers and female headers has the following advantages: fault tolerance, complementarity, instantaneity and economical efficiency. Therefore, multiple pin headers and female headers are promoted and applied gradually. In addition to military applications, they have been applied to automation technology, robotics, marine surveillance, seismic observation, construction, air traffic control, medical diagnosis, remote sensing technology and other aspects.

Sunkye Connection Technologies provides a wide product portfolio with a complete interconnect solutions offering. Sunkye connectors and cables assemblies are complementary with Sunkye backshells and conduits.

May 31, 2019

SUNKYE will Release Type C Project on October

May 31, 2019

SUNKYE will Release Type C Project on October

Apr 07, 2020

Market Status of Miniature Connectors

Apr 07, 2020

Market Status of Miniature Connectors

Feb 10, 2020

The Function And Prospect Of Medical Connector

Feb 10, 2020

The Function And Prospect Of Medical Connector

May 27, 2021

The Importance of Connectors in Electrical Equipment

May 27, 2021

The Importance of Connectors in Electrical Equipment

Jul 30, 2019

Market Status of Micro Connectors

Jul 30, 2019

Market Status of Micro Connectors

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Sep 24, 2019

Notes for Welding D Type Connector

Sep 24, 2019

Notes for Welding D Type Connector

Dec 08, 2019

Connection Methods Of The Connector

Dec 08, 2019

Connection Methods Of The Connector

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Apr 28, 2020

How to Detect Medical Connectors

Apr 28, 2020

How to Detect Medical Connectors

Jul 17, 2020

Sunkye Market Matrix

Jul 17, 2020

Sunkye Market Matrix

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Oct 19, 2021

Subsea Connector needs a new revolution

Oct 19, 2021

Subsea Connector needs a new revolution

Jun 12, 2020

7 Tips for Connector Design (1)

Jun 12, 2020

7 Tips for Connector Design (1)

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Nov 15, 2019

How To Make High-Quality Connector

Nov 15, 2019

How To Make High-Quality Connector

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Nov 11, 2019

Brief Introduction Of Automobile Connector

Nov 11, 2019

Brief Introduction Of Automobile Connector

Jan 04, 2023

Four Connection Methods of Circular Connectors

Jan 04, 2023

Four Connection Methods of Circular Connectors

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Aug 07, 2019

A Revolution in Connector Technology

Aug 07, 2019

A Revolution in Connector Technology

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

Sep 19, 2020

The Necessity of Waterproof Connectors

Sep 19, 2020

The Necessity of Waterproof Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Jan 11, 2021

How to Select Connectors for Hardware Design

Jan 11, 2021

How to Select Connectors for Hardware Design

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Sep 25, 2020

Related Knowledge of SMA RF Connector

Sep 25, 2020

Related Knowledge of SMA RF Connector

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Jun 15, 2020

7 Tips for Connector Design (2)

Jun 15, 2020

7 Tips for Connector Design (2)

Nov 04, 2019

How Military Connectors Work

Nov 04, 2019

How Military Connectors Work

Dec 29, 2019

Material Of Automotive Connectors

Dec 29, 2019

Material Of Automotive Connectors

Nov 24, 2019

The Connector Applications Are Everywhere

Nov 24, 2019

The Connector Applications Are Everywhere

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Oct 06, 2019

How Military Spec Connectors Work

Oct 06, 2019

How Military Spec Connectors Work

Aug 09, 2021

What Are High Density Connectors?

Aug 09, 2021

What Are High Density Connectors?

Dec 26, 2019

How To Classify Industrial Connectors

Dec 26, 2019

How To Classify Industrial Connectors

Oct 13, 2020

Selection Factors of RF Connectors

Oct 13, 2020

Selection Factors of RF Connectors

Jun 27, 2020

Crimping and Welding of Military Connectors

Jun 27, 2020

Crimping and Welding of Military Connectors

Oct 31, 2019

The Introduction Of SMT

Oct 31, 2019

The Introduction Of SMT

Dec 22, 2020

The Transient Interruption Detection of Connectors

Dec 22, 2020

The Transient Interruption Detection of Connectors

Sep 04, 2019

Market Profile of Micro PCB Connectors

Sep 04, 2019

Market Profile of Micro PCB Connectors

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Aug 02, 2021

Introduction to Vehicle Connectors

Aug 02, 2021

Introduction to Vehicle Connectors

Mar 20, 2020

Connector Quality Test Type

Mar 20, 2020

Connector Quality Test Type

Jan 07, 2020

The Performance Of Automobile Connector

Jan 07, 2020

The Performance Of Automobile Connector

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Jul 06, 2020

Manual Assembly of Connectors (2)

Jul 06, 2020

Manual Assembly of Connectors (2)

Sep 20, 2019

Strictness of Military/Aerospace Specifications

Sep 20, 2019

Strictness of Military/Aerospace Specifications

Sep 08, 2019

What are Avionics Connectors?

Sep 08, 2019

What are Avionics Connectors?

Jan 04, 2021

The Structure and Material of Connectors

Jan 04, 2021

The Structure and Material of Connectors

Apr 04, 2020

The Material of the Connector

Apr 04, 2020

The Material of the Connector

Nov 29, 2019

Importance Of Connectors

Nov 29, 2019

Importance Of Connectors

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Jan 01, 2020

Development Trend Of Automobile Connector In China

Jan 01, 2020

Development Trend Of Automobile Connector In China

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

Nov 17, 2023

Future Development Trends of Circular Connectors

Nov 17, 2023

Future Development Trends of Circular Connectors

Dec 17, 2019

Interconnection Level Of Connector

Dec 17, 2019

Interconnection Level Of Connector

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Dec 23, 2019

Technical Principles Of Connectors

Dec 23, 2019

Technical Principles Of Connectors

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Jan 13, 2020

Overall Performance Parameters Of Connector

Jan 13, 2020

Overall Performance Parameters Of Connector

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Jan 18, 2021

Knowledge of FPC Connectors

Jan 18, 2021

Knowledge of FPC Connectors

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Oct 20, 2020

The Failure Mechanism of Connectors

Oct 20, 2020

The Failure Mechanism of Connectors

Jul 18, 2020

The Basic Structure of the Connector

Jul 18, 2020

The Basic Structure of the Connector

Feb 08, 2021

Four Attention Points in Using Power Connectors

Feb 08, 2021

Four Attention Points in Using Power Connectors

Dec 11, 2019

The Main Classification Of Crimp Connection

Dec 11, 2019

The Main Classification Of Crimp Connection

Jan 31, 2020

The Development Of D-sub Connectors

Jan 31, 2020

The Development Of D-sub Connectors

Jan 28, 2020

The Connector Industry Is Booming

Jan 28, 2020

The Connector Industry Is Booming

Jul 03, 2020

Manual Assembly of Connectors (1)

Jul 03, 2020

Manual Assembly of Connectors (1)

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jun 24, 2020

Application of Military Electrical Connectors (3)

Jun 24, 2020

Application of Military Electrical Connectors (3)

Aug 02, 2020

Electrical Performance of Connector

Aug 02, 2020

Electrical Performance of Connector

Oct 06, 2020

Description of Pogo Pin Connectors

Oct 06, 2020

Description of Pogo Pin Connectors

Oct 01, 2020

Structure and Material of Waterproof Connector

Oct 01, 2020

Structure and Material of Waterproof Connector

Jan 22, 2020

Differences Between Connector And Terminal

Jan 22, 2020

Differences Between Connector And Terminal

Jul 15, 2020

Classification of Connectors

Jul 15, 2020

Classification of Connectors

Jun 18, 2020

Application of Military Electrical Connectors (1)

Jun 18, 2020

Application of Military Electrical Connectors (1)

Sep 26, 2019

Market Status of Micro Miniature Connectors

Sep 26, 2019

Market Status of Micro Miniature Connectors

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Nov 09, 2019

Introduction To Connector Knowledge

Nov 09, 2019

Introduction To Connector Knowledge

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Nov 06, 2019

Connector Classification

Nov 06, 2019

Connector Classification

Jul 21, 2020

What is a Military Specification Circular Connector?

Jul 21, 2020

What is a Military Specification Circular Connector?

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Feb 25, 2020

How to Choose the Right Medical Connector

Feb 25, 2020

How to Choose the Right Medical Connector

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Jul 12, 2020

Introduction to the Connector

Jul 12, 2020

Introduction to the Connector

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Apr 25, 2020

The Second Generation Circular Military Connector

Apr 25, 2020

The Second Generation Circular Military Connector

Nov 01, 2019

Five Common Features of USB Connector

Nov 01, 2019

Five Common Features of USB Connector

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Apr 01, 2020

Connectors for Special Applications

Apr 01, 2020

Connectors for Special Applications

Nov 08, 2019

Miniaturization Development Technology Of Connector

Nov 08, 2019

Miniaturization Development Technology Of Connector

Aug 03, 2019

Connector D Type

Aug 03, 2019

Connector D Type

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Aug 09, 2019

Development of Micro Connector

Aug 09, 2019

Development of Micro Connector

Sep 18, 2019

Definition of Mil Standard Connector

Sep 18, 2019

Definition of Mil Standard Connector

Jun 25, 2019

Sunkye Super Pin Datasheet

Jun 25, 2019

Sunkye Super Pin Datasheet

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Sep 02, 2019

Four Processes of Producing Connectors

Sep 02, 2019

Four Processes of Producing Connectors

Nov 12, 2019

Production Technology of Connector

Nov 12, 2019

Production Technology of Connector

May 31, 2019

Sunkye Type C 10Gbps Test on April

May 31, 2019

Sunkye Type C 10Gbps Test on April

May 31, 2019

Everything You Need to Know: Type C

May 31, 2019

Everything You Need to Know: Type C

May 31, 2019

Sunkye Super Pin Connector

May 31, 2019

Sunkye Super Pin Connector

Apr 22, 2020

Production Process of Connector Contacts

Apr 22, 2020

Production Process of Connector Contacts

Dec 14, 2019

Naming Of Connectors

Dec 14, 2019

Naming Of Connectors

Nov 14, 2019

How To Choose The Right Connector

Nov 14, 2019

How To Choose The Right Connector

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Jun 21, 2020

Application of Military Electrical Connectors (2)

Jun 21, 2020

Application of Military Electrical Connectors (2)

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

Jan 16, 2020

Brief Introduction Of Strip Connector

Jan 16, 2020

Brief Introduction Of Strip Connector

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Dec 02, 2019

Basic Structural Member Of Connector

Dec 02, 2019

Basic Structural Member Of Connector

Oct 13, 2020

Various Coaxial Connectors

Oct 13, 2020

Various Coaxial Connectors

May 04, 2020

Automotive Connectors

May 04, 2020

Automotive Connectors

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Oct 30, 2019

D Sub Connector Introduction

Oct 30, 2019

D Sub Connector Introduction

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Sep 13, 2020

Fusion of Connectors and Sensors

Sep 13, 2020

Fusion of Connectors and Sensors

Dec 08, 2020

Some Knowledge about RJ45 Connector

Dec 08, 2020

Some Knowledge about RJ45 Connector

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Feb 13, 2020

Connection Between Brain And Machine

Feb 13, 2020

Connection Between Brain And Machine

May 31, 2019

Features of Type C

May 31, 2019

Features of Type C

Nov 17, 2020

Selection Factors for SMA Connectors

Nov 17, 2020

Selection Factors for SMA Connectors

Nov 10, 2019

The Future Trend Of Automobile Connector

Nov 10, 2019

The Future Trend Of Automobile Connector

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Oct 10, 2019

Types and Advantages of D-sub Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

GET IN TOUCH

MIL-DTL-32139 Nano D Connectors

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  Türkçe

Türkçe  Svenska

Svenska  Nederland

Nederland