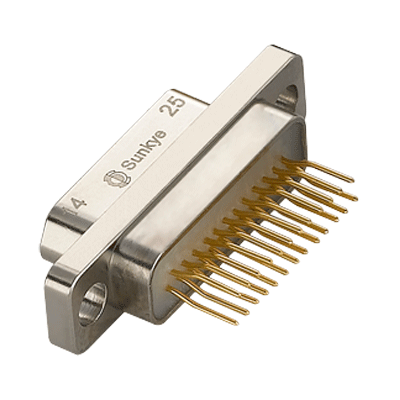

MIL-DTL-83513 Micro D Connectors

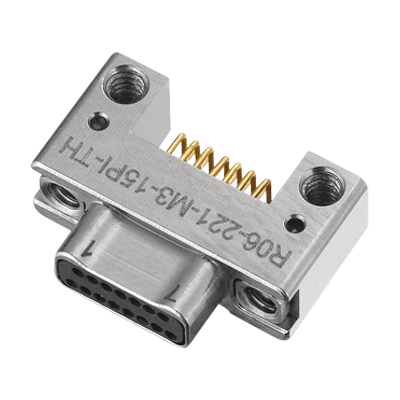

MIL-DTL-32139 Nano D Connectors

Discover more applications using Sunkye Connectors' solutions

The main function is to connect various devices. The working voltage of the aerospace connector plug is required to be below 12 volts. The aerospace plug can maintain a continuous working current due to its structural advantages, and the current flowing through it is very small.

1. Vibration and shock resistance is an important performance of aerospace connector plugs. It is particularly important in special application environments such as aviation and aerospace, railway and road transportation. It is important indicators to test the robustness and electrical contact reliability of aerospace plugs and connectors;

2. Humidity-resistant aerospace plugs and connectors: the intrusion of moisture will affect the insulation performance of the plug-in connection and rust metal parts;

3. Temperature resistance.

1. Please do not disassemble and assemble the aerospace connector plug in a live state, otherwise it will be dangerous due to sparks, etc., or cause poor performance;

2. When the aerospace connector plug is exposed to condensation or wet, it may cause poor insulation between circuits. If condensation or water is likely to occur, please take appropriate waterproof measures;

3. When using the aerospace connector plug, do not branch the current above the rated value into multiple circuits for energization;

4. When using the aerospace connector plug row, if the resonance of the wires installed on the terminal, the printed wiring board, or the rotation structure of the equipment and the movement of the movable part, the terminal connector (connecting part) is always used for partial use, poor contact may be caused due to sliding wear of the contact part.

1. Rated voltage and current

The same withstand voltage index of aerospace connector plug can use different maximum working voltage according to different using environment and safety requirements. To limit the rated current, in fact, it is necessary to limit the temperature rise inside the electrical connector not to exceed the specified value of the design. The problem that we should pay attention to when choosing is: For multi-core electrical connectors, the rated current must be derated for use.

2. Installation method and appearance

The shape of the aerospace connector plug terminal is ever-changing. The user mainly chooses from the straight shape, the curved shape, the outer diameter of the wire or cable and the fixing requirements with the shell, the volume, the weight, whether to connect the metal hose, etc. The electrical connector used on the panel should be selected from the aspects of beauty, shape, color and so on.

3. Electrical parameter requirements

Aerospace connectors are electromechanical components that connect electrical circuits. Therefore, the electrical parameters of the aerospace connector itself are the first consideration when choosing a connector.

Sunkye Connection Technologies provides a wide product portfolio with a complete interconnect solutions offering. Sunkye connectors and cables assemblies are complementary with Sunkye backshells and conduits.

Jul 06, 2020

Manual Assembly of Connectors (2)

Jul 06, 2020

Manual Assembly of Connectors (2)

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Jun 06, 2019

Alloy 52 UNS N14052 Material Report

Sep 08, 2019

What are Avionics Connectors?

Sep 08, 2019

What are Avionics Connectors?

Sep 04, 2019

Market Profile of Micro PCB Connectors

Sep 04, 2019

Market Profile of Micro PCB Connectors

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Mar 08, 2020

Sunkye: Safety, Innovation, Reliability

Nov 06, 2019

Connector Classification

Nov 06, 2019

Connector Classification

Sep 26, 2019

Market Status of Micro Miniature Connectors

Sep 26, 2019

Market Status of Micro Miniature Connectors

Feb 10, 2020

The Function And Prospect Of Medical Connector

Feb 10, 2020

The Function And Prospect Of Medical Connector

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Nov 23, 2022

Hermetic Connectors for Implantable Medical Devices

Dec 08, 2019

Connection Methods Of The Connector

Dec 08, 2019

Connection Methods Of The Connector

Sep 13, 2020

Fusion of Connectors and Sensors

Sep 13, 2020

Fusion of Connectors and Sensors

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Nov 05, 2019

Wearable Connectors Tend to be Miniaturization

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Dec 01, 2020

How to Improve the Reliability of RF Connectors

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Jan 03, 2024

Connector — A Big Player in Your Supply Chain

Dec 08, 2020

Some Knowledge about RJ45 Connector

Dec 08, 2020

Some Knowledge about RJ45 Connector

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Sep 08, 2022

How Does Environment Temperature Affect Connectors?

Dec 29, 2019

Material Of Automotive Connectors

Dec 29, 2019

Material Of Automotive Connectors

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

Oct 02, 2023

MEET SUNKYE AT ADIPEC 2023 FAIR

May 31, 2019

Sunkye Type C 10Gbps Test on April

May 31, 2019

Sunkye Type C 10Gbps Test on April

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Mar 29, 2020

Demand for Heavy Truck Connectors Increases

Sep 25, 2020

Related Knowledge of SMA RF Connector

Sep 25, 2020

Related Knowledge of SMA RF Connector

Nov 09, 2019

Introduction To Connector Knowledge

Nov 09, 2019

Introduction To Connector Knowledge

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Aug 19, 2024

Can a Connector Withstand Temperatures Up to 500°C?

Feb 13, 2020

Connection Between Brain And Machine

Feb 13, 2020

Connection Between Brain And Machine

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Jan 23, 2026

Building the Backbone of Deep Sea Sensing

Nov 11, 2019

Brief Introduction Of Automobile Connector

Nov 11, 2019

Brief Introduction Of Automobile Connector

Dec 26, 2019

How To Classify Industrial Connectors

Dec 26, 2019

How To Classify Industrial Connectors

Oct 31, 2019

The Introduction Of SMT

Oct 31, 2019

The Introduction Of SMT

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Sep 28, 2019

Development Trend of Miniature Connectors Technology

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Sep 14, 2019

Miniaturization Trend of Mil Connectors

Oct 30, 2019

D Sub Connector Introduction

Oct 30, 2019

D Sub Connector Introduction

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Feb 15, 2021

The Power Capacity of RF Coaxial Connectors

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Jul 09, 2020

The Importance of Connectors in Medical Equipment

Dec 22, 2020

The Transient Interruption Detection of Connectors

Dec 22, 2020

The Transient Interruption Detection of Connectors

May 31, 2019

SUNKYE will Release Type C Project on October

May 31, 2019

SUNKYE will Release Type C Project on October

Mar 20, 2020

Connector Quality Test Type

Mar 20, 2020

Connector Quality Test Type

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Dec 01, 2021

Connectors' Revolution of 1000km off The Earth

Nov 24, 2019

The Connector Applications Are Everywhere

Nov 24, 2019

The Connector Applications Are Everywhere

Jan 18, 2021

Knowledge of FPC Connectors

Jan 18, 2021

Knowledge of FPC Connectors

Dec 23, 2019

Technical Principles Of Connectors

Dec 23, 2019

Technical Principles Of Connectors

Jun 24, 2020

Application of Military Electrical Connectors (3)

Jun 24, 2020

Application of Military Electrical Connectors (3)

Nov 10, 2019

The Future Trend Of Automobile Connector

Nov 10, 2019

The Future Trend Of Automobile Connector

Jan 13, 2020

Overall Performance Parameters Of Connector

Jan 13, 2020

Overall Performance Parameters Of Connector

Jul 17, 2020

Sunkye Market Matrix

Jul 17, 2020

Sunkye Market Matrix

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Jun 01, 2021

Functions and Advantages of Electrical Connectors

Sep 24, 2019

Notes for Welding D Type Connector

Sep 24, 2019

Notes for Welding D Type Connector

Apr 25, 2020

The Second Generation Circular Military Connector

Apr 25, 2020

The Second Generation Circular Military Connector

Jul 15, 2020

Classification of Connectors

Jul 15, 2020

Classification of Connectors

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Dec 18, 2025

How to Survive During the Low Earth Orbit (LEO)?

Apr 07, 2020

Market Status of Miniature Connectors

Apr 07, 2020

Market Status of Miniature Connectors

Nov 17, 2023

Future Development Trends of Circular Connectors

Nov 17, 2023

Future Development Trends of Circular Connectors

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Aug 15, 2023

Extreme Conditions Bring up Hermetic Connectors

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Sep 21, 2021

Connection Mode and Purchase of Aerospace Connector

Jan 31, 2020

The Development Of D-sub Connectors

Jan 31, 2020

The Development Of D-sub Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Nov 10, 2020

The Manufacturing Process of Electronic Connectors

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Jan 25, 2020

Four Types Of Industrial Electrical Connectors

Oct 06, 2019

How Military Spec Connectors Work

Oct 06, 2019

How Military Spec Connectors Work

Feb 25, 2020

How to Choose the Right Medical Connector

Feb 25, 2020

How to Choose the Right Medical Connector

Sep 19, 2020

The Necessity of Waterproof Connectors

Sep 19, 2020

The Necessity of Waterproof Connectors

Dec 11, 2019

The Main Classification Of Crimp Connection

Dec 11, 2019

The Main Classification Of Crimp Connection

May 31, 2019

Everything You Need to Know: Type C

May 31, 2019

Everything You Need to Know: Type C

Oct 19, 2021

Subsea Connector needs a new revolution

Oct 19, 2021

Subsea Connector needs a new revolution

Jun 27, 2020

Crimping and Welding of Military Connectors

Jun 27, 2020

Crimping and Welding of Military Connectors

Jun 21, 2020

Application of Military Electrical Connectors (2)

Jun 21, 2020

Application of Military Electrical Connectors (2)

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Sep 06, 2019

Polytetrafluoroethylene-PTFE

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Jul 17, 2024

MEET SUNKYE AT ONS 2024

Nov 15, 2019

How To Make High-Quality Connector

Nov 15, 2019

How To Make High-Quality Connector

Jan 22, 2020

Differences Between Connector And Terminal

Jan 22, 2020

Differences Between Connector And Terminal

Jul 30, 2019

Market Status of Micro Connectors

Jul 30, 2019

Market Status of Micro Connectors

Jun 12, 2020

7 Tips for Connector Design (1)

Jun 12, 2020

7 Tips for Connector Design (1)

Aug 09, 2021

What Are High Density Connectors?

Aug 09, 2021

What Are High Density Connectors?

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Nov 02, 2021

MEET SUNKYE AT SAHA EXPO 2021 FAIR!

Jan 28, 2020

The Connector Industry Is Booming

Jan 28, 2020

The Connector Industry Is Booming

Apr 28, 2020

How to Detect Medical Connectors

Apr 28, 2020

How to Detect Medical Connectors

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Apr 13, 2020

Why is a Poor Connector Prone to Fire?

Jun 15, 2020

7 Tips for Connector Design (2)

Jun 15, 2020

7 Tips for Connector Design (2)

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jul 08, 2021

Structural Analysis of Aerospace Connector

Jan 04, 2021

The Structure and Material of Connectors

Jan 04, 2021

The Structure and Material of Connectors

Apr 04, 2020

The Material of the Connector

Apr 04, 2020

The Material of the Connector

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

May 31, 2019

Sunkye at Expo Electronica 2014, Moscow

May 31, 2019

Sunkye Super Pin Connector

May 31, 2019

Sunkye Super Pin Connector

Aug 07, 2019

A Revolution in Connector Technology

Aug 07, 2019

A Revolution in Connector Technology

Jun 25, 2019

Sunkye Super Pin Datasheet

Jun 25, 2019

Sunkye Super Pin Datasheet

Dec 14, 2019

Naming Of Connectors

Dec 14, 2019

Naming Of Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Dec 05, 2019

Disassembly Tools For Automotive Connectors

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Oct 07, 2020

How to Distinguish FFC Connector and FPC Connector

Jul 21, 2020

What is a Military Specification Circular Connector?

Jul 21, 2020

What is a Military Specification Circular Connector?

Jan 07, 2020

The Performance Of Automobile Connector

Jan 07, 2020

The Performance Of Automobile Connector

Aug 03, 2019

Connector D Type

Aug 03, 2019

Connector D Type

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Jan 19, 2020

Brief Introduction Of Flat Cable Connector

Jan 11, 2021

How to Select Connectors for Hardware Design

Jan 11, 2021

How to Select Connectors for Hardware Design

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Feb 07, 2020

The Rapidly Growing Market For Medical Connectors

Jul 03, 2020

Manual Assembly of Connectors (1)

Jul 03, 2020

Manual Assembly of Connectors (1)

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Nov 03, 2020

The Guide for Selecting Electrical Connectors

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Nov 10, 2020

Applications and Characteristics of BNC Connectors

Jun 18, 2020

Application of Military Electrical Connectors (1)

Jun 18, 2020

Application of Military Electrical Connectors (1)

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Oct 18, 2022

Hermetic Connectors for Implantable Medical Devices

Apr 01, 2020

Connectors for Special Applications

Apr 01, 2020

Connectors for Special Applications

May 27, 2021

The Importance of Connectors in Electrical Equipment

May 27, 2021

The Importance of Connectors in Electrical Equipment

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

May 31, 2019

TWIST PIN: THE LIGHTSPOT OF SUNKYE

Aug 02, 2021

Introduction to Vehicle Connectors

Aug 02, 2021

Introduction to Vehicle Connectors

Oct 06, 2020

Description of Pogo Pin Connectors

Oct 06, 2020

Description of Pogo Pin Connectors

Apr 22, 2020

Production Process of Connector Contacts

Apr 22, 2020

Production Process of Connector Contacts

Dec 17, 2019

Interconnection Level Of Connector

Dec 17, 2019

Interconnection Level Of Connector

Jul 12, 2020

Introduction to the Connector

Jul 12, 2020

Introduction to the Connector

Nov 04, 2019

How Military Connectors Work

Nov 04, 2019

How Military Connectors Work

Feb 08, 2021

Four Attention Points in Using Power Connectors

Feb 08, 2021

Four Attention Points in Using Power Connectors

Nov 17, 2020

Selection Factors for SMA Connectors

Nov 17, 2020

Selection Factors for SMA Connectors

Aug 09, 2019

Development of Micro Connector

Aug 09, 2019

Development of Micro Connector

Jul 18, 2020

The Basic Structure of the Connector

Jul 18, 2020

The Basic Structure of the Connector

Oct 20, 2020

The Failure Mechanism of Connectors

Oct 20, 2020

The Failure Mechanism of Connectors

Oct 13, 2020

Various Coaxial Connectors

Oct 13, 2020

Various Coaxial Connectors

Oct 13, 2020

Selection Factors of RF Connectors

Oct 13, 2020

Selection Factors of RF Connectors

Jan 04, 2023

Four Connection Methods of Circular Connectors

Jan 04, 2023

Four Connection Methods of Circular Connectors

Nov 29, 2019

Importance Of Connectors

Nov 29, 2019

Importance Of Connectors

Nov 08, 2019

Miniaturization Development Technology Of Connector

Nov 08, 2019

Miniaturization Development Technology Of Connector

Nov 14, 2019

How To Choose The Right Connector

Nov 14, 2019

How To Choose The Right Connector

Sep 18, 2019

Definition of Mil Standard Connector

Sep 18, 2019

Definition of Mil Standard Connector

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Oct 13, 2023

Several Design Ideas for Electronic Connectors

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Jan 25, 2021

The Analysis of Connector Electroplating Problems

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Sep 12, 2019

Reliable Connectors Are the Secret of UAV Success

Sep 20, 2019

Strictness of Military/Aerospace Specifications

Sep 20, 2019

Strictness of Military/Aerospace Specifications

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

May 10, 2020

Reliability of Aerospace Electrical Connectors (1)

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

Dec 22, 2024

Specialty Gas Connectors for Niche Applications

May 04, 2020

Automotive Connectors

May 04, 2020

Automotive Connectors

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Nov 01, 2021

Meet Sunkye at SEDEC 2020 Fair!

Nov 12, 2019

Production Technology of Connector

Nov 12, 2019

Production Technology of Connector

Sep 02, 2019

Four Processes of Producing Connectors

Sep 02, 2019

Four Processes of Producing Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Feb 19, 2020

Reliability of Aerospace Electrical Connectors

Dec 02, 2019

Basic Structural Member Of Connector

Dec 02, 2019

Basic Structural Member Of Connector

May 31, 2019

Features of Type C

May 31, 2019

Features of Type C

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

May 13, 2020

Reliability of Aerospace Electrical Connectors (2)

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Aug 01, 2022

Connectors Make Sensors Work Well on Equipment

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Nov 17, 2022

Robotic Arm Works 7*24 in Manufacturing

Oct 01, 2020

Structure and Material of Waterproof Connector

Oct 01, 2020

Structure and Material of Waterproof Connector

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

May 31, 2019

Sunkye Will Postpone the Release of USB 3.1 Type C

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Oct 25, 2024

Harnessing Wind Energy: Sustainable Power Solutions

Jan 16, 2020

Brief Introduction Of Strip Connector

Jan 16, 2020

Brief Introduction Of Strip Connector

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Nov 03, 2019

Some Solutions For Poor Terminal Pressing

Nov 01, 2019

Five Common Features of USB Connector

Nov 01, 2019

Five Common Features of USB Connector

Aug 02, 2020

Electrical Performance of Connector

Aug 02, 2020

Electrical Performance of Connector

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Sep 28, 2021

Correct Use and Safety of Avionics Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Oct 10, 2019

Types and Advantages of D-sub Connectors

Jan 01, 2020

Development Trend Of Automobile Connector In China

Jan 01, 2020

Development Trend Of Automobile Connector In China

GET IN TOUCH

MIL-DTL-32139 Nano D Connectors

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  Türkçe

Türkçe  Svenska

Svenska  Nederland

Nederland