The Harsh Reality of Oil & Gas Operations

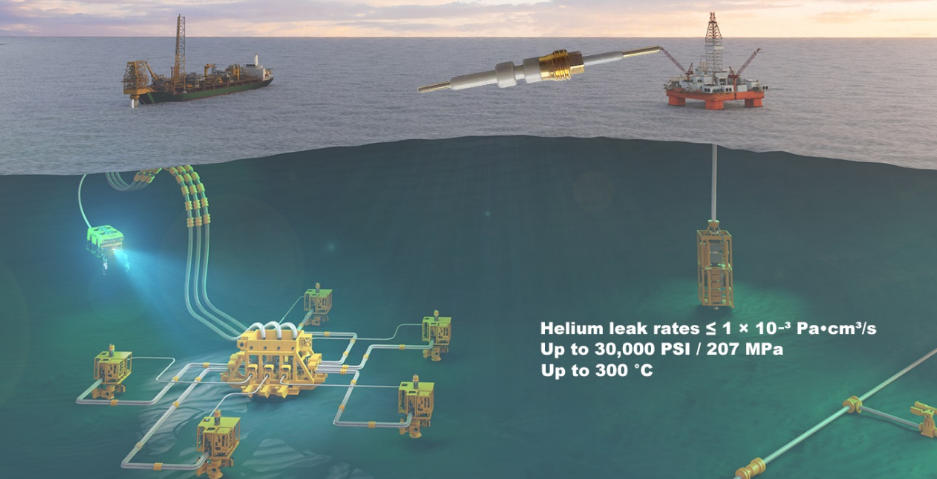

Oil & gas and petrochemical environments are some of the toughest engineering frontiers — characterized by high pressure, extreme temperatures, chemical corrosion, low-pH erosion, and exposure to aggressive gases.

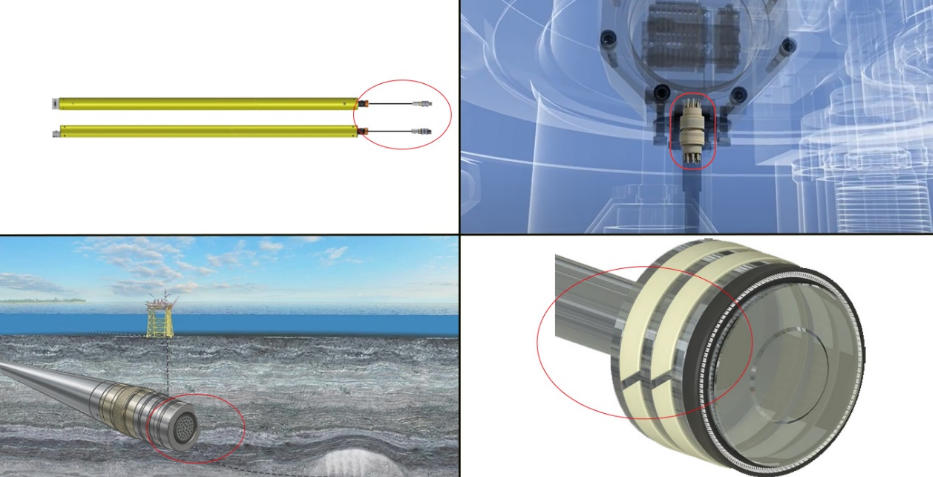

In these demanding conditions, PEEK (Polyether Ether Ketone) has emerged as a preferred polymer for connectors, sealing terminals, and other precision components.

What Makes PEEK Stand Out

PEEK provides exceptional durability and stability when metals and conventional plastics fail.

Key Performance Highlights:

· Pressure resistance: up to 30,000 PSI / 207 MPa

· Working temperature: up to 300 °C

· Chemical stability: withstands acids, crude oil, and corrosive gases

· Electrical insulation: ideal for signal and power transmission under HTHP conditions

· Machinability: compatible with CNC precision processing

For applications requiring extreme hermeticity, glass-to-metal sealing can be integrated with PEEK components.

This technique ensures helium leak rates ≤ 1 × 10⁻³ Pa·cm³/s, with no trapped air bubbles and superior sealing reliability.

Typical Applications

PEEK’s unique mechanical and chemical performance enables reliable operation in a wide range of oil & gas applications:

· Hydrophone housings

· Hydraulic control line adapter spools (C/L terminations)

· Electrical cable fittings and subsea connectors

· Seals, valve seats, and gate valve components

· Downhole tool interconnections

· Backup rings and bushings

· Tubing-head spools and control line outlets

· Gears and structural housings

These components benefit from light weight, corrosion resistance, thermal isolation, and noise reduction, all contributing to longer service life and reduced maintenance.

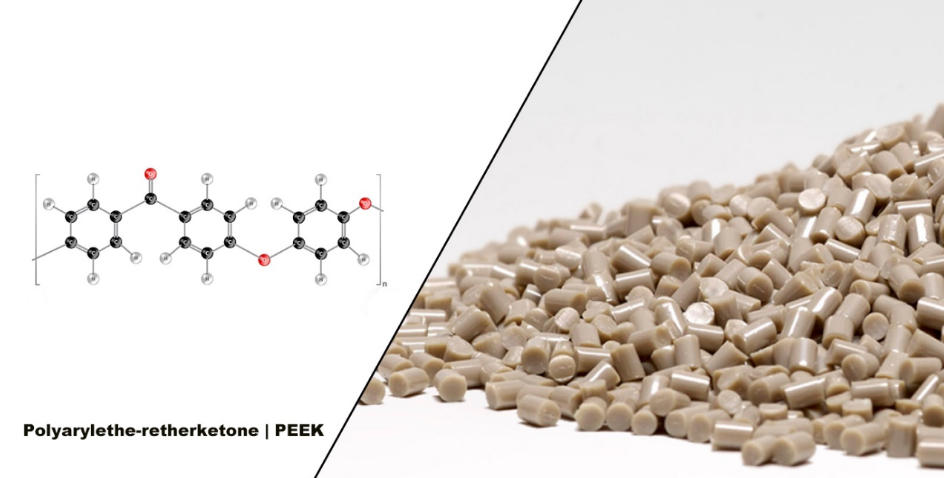

Understanding PEEK

Polyether Ether Ketone (PEEK) is a high-performance thermoplastic in the polyaryletherketone (PAEK) family.

It retains its mechanical integrity under prolonged heat and chemical exposure.

Core Properties:

· Continuous operating temperature up to 260 °C (500 °F)

· Resistant to halogens, strong acids, and thermal degradation

· Melting point: 343 °C / 649 °F

· Easily machined or injection-molded into complex parts

· Available in filled grades (e.g., 30% glass-filled PEEK) for enhanced rigidity

Because of these characteristics, PEEK is considered a high-performance polymer, typically reserved for mission-critical applications in oil & gas, aerospace, and medical systems.

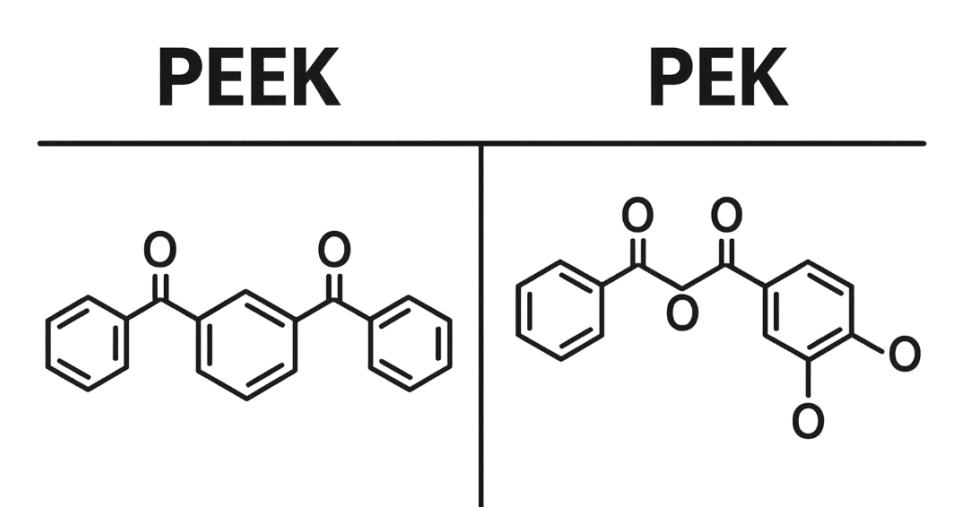

PEEK vs. PEK — Know the Difference

While both PEEK (Polyether Ether Ketone) and PEK (Polyether Keton) belong to the same polymer family, PEEK’s additional ether linkage provides:

· Higher molecular flexibility

· Better thermal stability

· Greater resistance to stress cracking

Category | PEEK | PEK (Polyether Ketone) | Technical Impact |

- | (Polyether Ether Ketone) | - | - |

Repeating Unit | –O–Ph–O–Ph–CO–Ph– | –O–Ph–CO–Ph–CO–Ph– | Position & amount of ketone groups differ |

Ketone Groups/Unit | 1 | 2 | PEK has higher chain rigidity & polarity |

Ether Groups/Unit | 2 | 1 | PEEK maintains better flexibility |

Chain Flexibility | Medium (more ether linkages) | Lower (more ketone linkages) | PEK = stiffer backbone |

Chain Polarity | Medium | Higher | Affects dielectric & thermal behavior |

Thermal Stability | High | Very high | Extra ketone increases heat resistance |

Melting Point (Tm) | ~343°C | ~372°C | PEK is more difficult to process |

Crystallinity | High | High | Both form strong semi-crystalline structures |

When choosing materials for HTHP connectors or sealing terminals, ensure the insulator is true PEEK, not PEK, to guarantee long-term performance and reliability.

Testing Capability & Qualification

Pressure and temperature endurance tests

A. Static Pressure Test

Test Method: API 17D

Pressure: 20,300psi

Time:4h

Acceptance Criteria: The connectors should be no visible external leakage is allowed during the test Internal pressure shall remain stable within the specified tolerance.

Sunkye’s Result: Passed

B. Dynamic Pressure Cycling

Test Method: API 6A/ API 17D/ API 17F Section 9.2.2.1/ EIA-364-39

Requirement: 520 pressure cycles, from 0 to 20,300psi

Depressurization rate: 100 psi/s

Acceptance Criteria: Samples shall pass Electrical Verification Tests and exhibit no damage detrimental to functionality.

Sunkye’s Result: Passed

C. Continuous operating temperature

Test Method: API 6A Class K

Requirement: Samples placed in a calibrated high-temperature air oven.

Temperature setting: 150℃~200℃

Time:72h

Acceptance Criteria: Samples shall pass Electrical Verification Tests and exhibit no damage detrimental to functionality.

Sunkye’s Result: Passed

Dielectric Strength And Insulation Resistance

A. Withstand Voltage

Test Method: GJB 1217A-2009 Method 3001/ MIL-STD-202 Method 301

Requirement: Samples should be applied 500 VDC for 1 min between contacts and body

Acceptance Criteria: No breakdown

Sunkye’s Result: ≥1000VDC 60s, Passed

B. Insulation Resistance

Test Method: MIL-STD-202 Method 302/ API 6A / 17D

Requirement: Samples should be assemblies with PEEK dielectric insert, Mated pairs or bulkhead / feedthrough structures.

Insulation Resistance:≥5GΩ at 1000VDC 60s

Sunkye’s Result: >10GΩ at 1000VDC 60s, Passed

Shock and Vibration

A. Shock

Test Method: MIL-STD-202 Method 213/214/ API 17D

Shock: 50g, 11ms

Direction:X/Y/Z

Cycles:≥ 3times/direction

Acceptance Criteria: Electrical Monitoring: Continuous continuity monitoring; no discontinuities ≥ 1 µs

Sunkye’s Result: Passed

B. Vibration

Test Method:API 17D / API 17F / IEC 60068-2-6 / MIL-STD-202 Method 204

Sine vibration:10Hz~2000Hz, 20g on direction X, Y, Z

Random vibration: 0.3G2/Hz, acceleration 20G,.4h on direction X, Y, Z

Acceptance Criteria: Electrical Monitoring: Continuous continuity monitoring; no discontinuities ≥ 1 µs

Sunkye’s Result: Passed

Thermal Cycling And Aging Validation

A. Thermal Cycling

Test Method: EIA-364-32/ MIL-STD-202 Method 107

Temperature Extreme: -55°C~+200°C for 60 minutes at each temperature extreme, 15 cycles

Acceptance Criteria: The samples must pass electrical verification testing and exhibit no damage detrimental to functionality.

Sunkye’s Result: Passed

B. Aging Validation

Test Method: API 6A Annex G/ ASTM D3045/ EIA-364-20/21

Item | Parameter | Notes |

Aging Method | Thermal Aging (Air-Circulating Oven) | Dry, forced-air convection |

Set Temperature | 150°C / 175°C / 200°C (per requirement) | Selected based on qualification level |

Temperature Tolerance | ±2°C | Per ISO 23936 / M-710 requirement |

Exposure Duration | 500 h / 1000 h | Defined by aging profile |

Chamber Type | Calibrated high-temperature oven | Uniformity verified before test |

Monitoring Interval | Every 1–2 hours | Time and chamber temperature logged |

Inspection Points | 0 h, 100 h, 250 h, 500 h, 750 h, 1000 h | Used to record oxidation and physical changes |

Specimen Condition | Unpowered, free-standing | Unless otherwise specified |

Post-Aging Evaluation | Visual, dimensional, IR, DWV, contact resistance | Compared to baseline values |

Evaluation Item | Sunkye’s Result |

Temperature Stability | PASS |

Oxidation / Surface Aging | PASS |

PEEK Insulator Condition | PASS |

Seal Condition | PASS |

Dimensional Stability | PASS |

Insulation Resistance | PASS |

Dielectric Withstand (DWV) | PASS |

Contact Resistance Shift | PASS |

Overall Verdict | PASS |

Helium Leak Test

Test Method: MIL-STD-883 Method 1014

Requirement: ≤ 1 × 10⁻³ Pa·cm³/s

Acceptance Criteria: No drift or spike in leak rate, stable value during measurement

Sunkye’s Result: Passed

Corrosion And Low-Ph Compatibility Evaluation

A. Salt Spray

Test Method: API 6A/ ASTM B117/ ISO 9227

Salt Concentration: 5% NaCl

PH: 6.5–7.2

Temperature: Environment Temperature

Duration: 48h

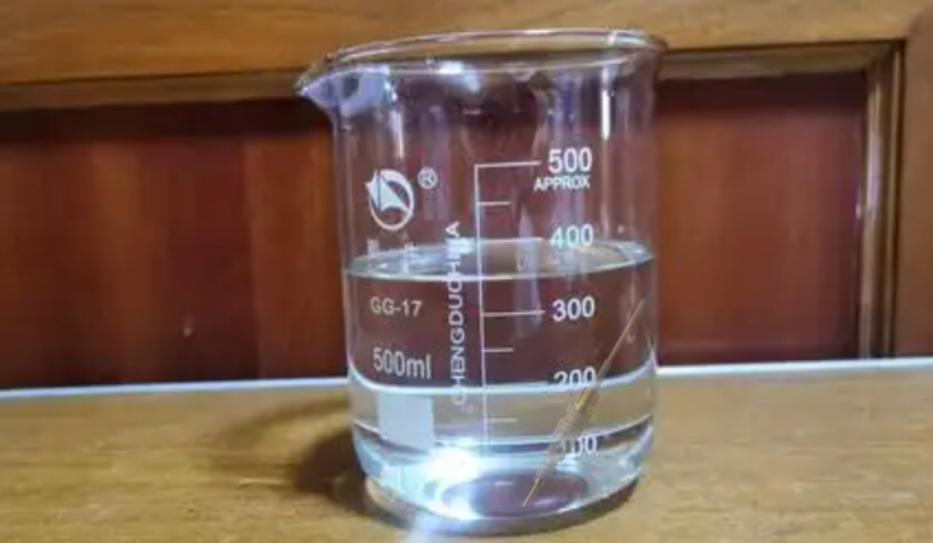

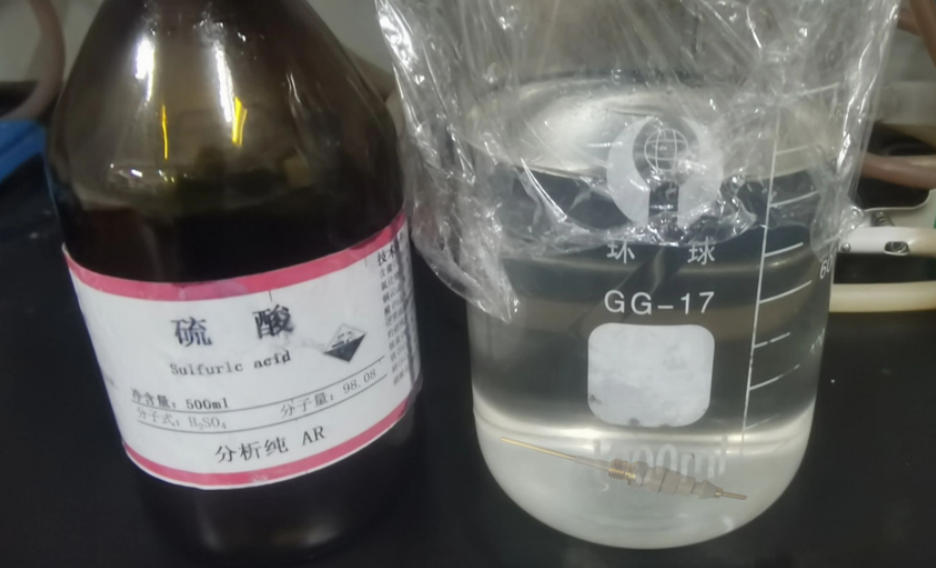

B. Acidic Immersion Test

Test Method: ASTM D543/ ISO 23936-1 / NORSOK M-710

PH: 2–4 Acidic (HCl / H₂SO₄)

Temperature: Environment Temperature

Duration: 10h

C. Crude Oil Immersion

Test Method: ISO 23936-1 / NORSOK M-710

Fluid: Crude oil or synthetic hydrocarbon

Temperature: Environment Temperature

Duration: 48h

D. Seawater Testing

Test Method: ASTM D1141/ ISO 23936 / M-710

Fluid: Synthetic Seawater

Temperature: Environment Temperature

Duration: 48h

Test Type | Acceptable Mechanical Results | Acceptable Electrical Results | Sunkye |

Salt Spray | No red rust; no pitting; no blistering; plating intact | IR ≥ 5,000 MΩ; DWV Pass | Passed |

Acidic (Low-pH) | No metal loss; no PEEK cracking/whitening; seal swell ≤ 20% | IR ≥ 5,000 MΩ; DWV Pass | Passed |

Crude Oil | No polymer softening; mass change ≤ 5%; seal swell ≤ 20% | IR ≥ 5,000 MΩ; DWV Pass | Passed |

Seawater/Brine | No pitting; no creep/corrosion; no polymer degradation | IR ≥ 5,000 MΩ; DWV Pass | Passed |

This section demonstrates that Sunkye’s PEEK-based sealing and connector solutions are qualified for harsh downhole, subsea, and topside environments.

Final Thoughts

As energy exploration pushes deeper and harsher, PEEK materials continue to redefine what’s possible in reliability and performance.

At Sunkye International, we specialize in custom HTHP interconnect and sealing solutions based on advanced materials like PEEK, ensuring long-term stability under the most challenging conditions.

Follow Sunkye for more insights on material innovations and high-reliability connector technologies.

Popular Searches

Explore Our Industry & Solution

Sunkye Connection Technologies provides a wide product portfolio with a complete interconnect solutions offering. Sunkye connectors and cables assemblies are complementary with Sunkye backshells and conduits.

GET IN TOUCH

MIL-DTL-32139 Nano D Connectors